The Simple Science

In Layman’s terms

Controlled vs. uncontrolled systems.

In simple terms: Our intellectual property adds an element of the heat which would under normal circumstances be generated by the compressor, allowing the compressor or compressors to unload. This process accelerates the heat transfer at condensation point, thus improving the quantity of liquid flow through the expansion valve, in other words reducing or eradicating flash gas. (see our video) As a result, the cooling capacity in the evaporator is enhanced, a process which the systems normal control logic recognises allowing the variable flow compressor system to slow down (or if staged - shut down), thus achieving substantial energy reductions.

Over recent years the ‘old’ single fixed speed compressor (un-controlled) has started to be replaced by more efficient rack systems (staged fixed speed compressors), and more recently variable speed systems (frequency controlled). The single fixed speed system is exactly that, it comes on at one speed and goes off at one speed. Therefore it would run at full speed (and energy consumption), even if the building or refrigerator required only a small load.

Today’s staged and variable technology however provides us with an ‘engine’ with variable speed, therefore we now have a system with a considerably improved correlation between demand and production. We now have an engine (the compressor), which has the ability to slow down in variable or staged modes, simply because we implement a ‘tail wind’ (the third party heat source i.e. a Solar Thermal Collection System) allowing the engine to take advantage of that tail wind, therefore achieving the original speed (the cooling capacity) without the additional fuel consumption.

Thermodynamics of ThermX™

The well-known compressor technology is enhanced with a proprietary developed solar thermal collection system. We now have a super advanced compressor system.

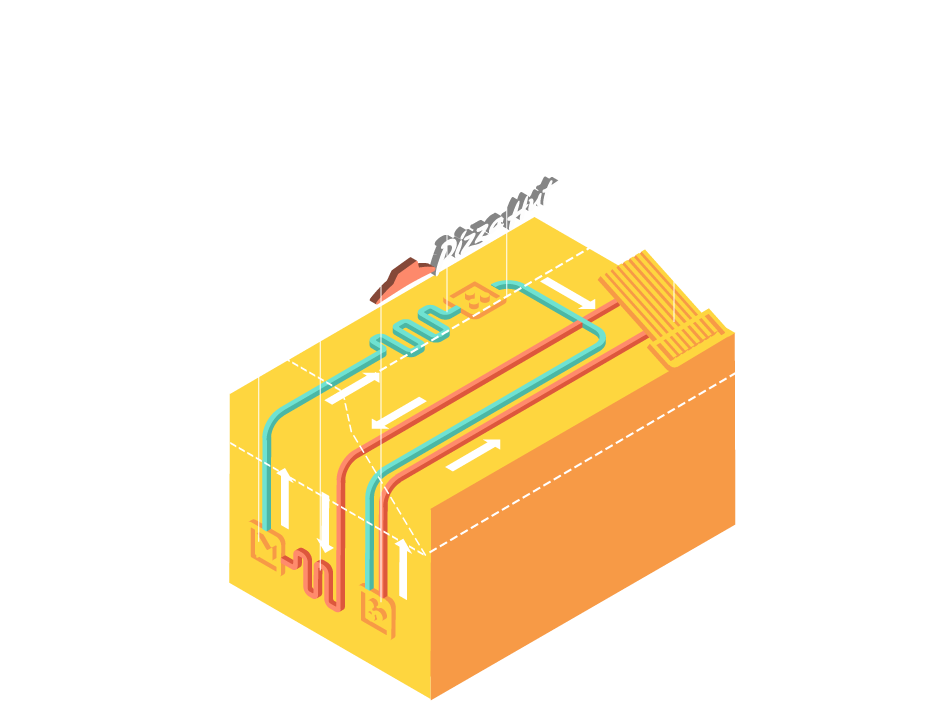

ThermX™ uses an exclusive patented process, of placing a 3-party heat exchanger between Compressor and Condenser. Utilizing the free available energy from the sun to heat the refrigerant & subsequently reducing the workload of the compressor/s.

As the free energy from the sun heats the refrigerant, it is provided with thermal energy, this in turn raises the internal energy (the sum of all microscopic kinetic and potential energy of the molecules).

The molecules now move with a higher value of kinetic energy, which simply implies each molecule moves with a higher velocity than before. Now the molecules collide more often with one another and rebound with an increased energy…

…which in turn creates an improved Delta T at the condenser, increased sub-cooling and better quality of liquid at expansion.

- resulting in an unequalled cooling and heating process.

The hotter the sun shines, the more the solar takes over the heating of the gas and the more power is saved. The compressor acts now mainly as a pump, providing the necessary cycle flow.The reason clients use our

systems for heating

How the heating system works

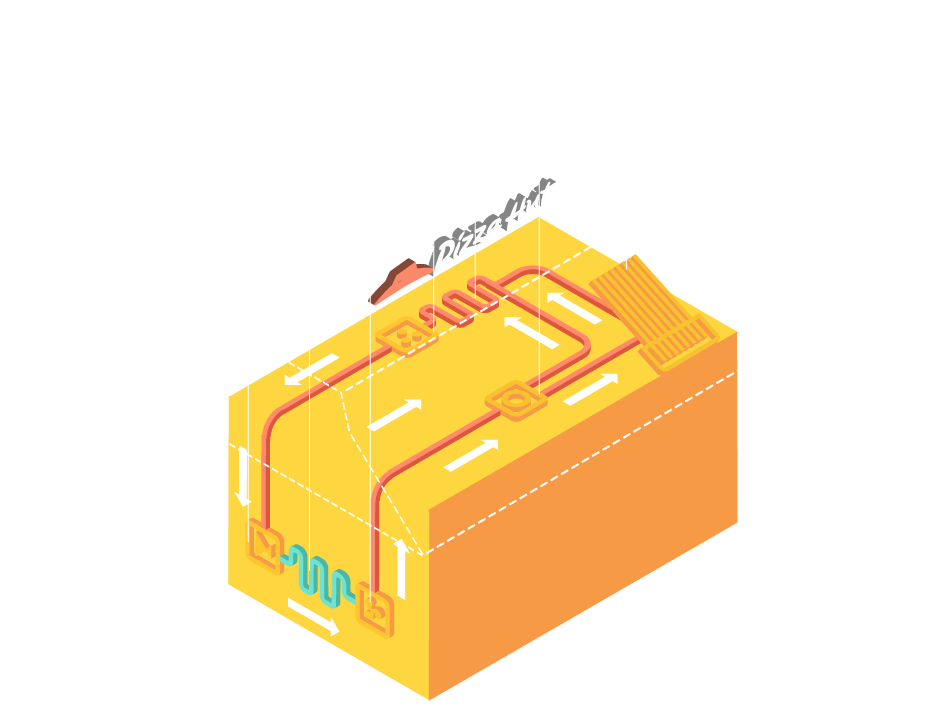

In heating mode the system works in almost the same way, but now the flow changes compared to the cooling mode. The additional free heating of the refrigerant in the solar panel allows the compressor to reduce its load, and therefore, its power consumption. Dependent on sun levels, COP figures (heating capacity vs power consumption) of over 8 are possible!

Again the more the sun shines, the more the solar panel takes over the compressing of the gas and the more power is saved, as the compressor now acts mainly as a pump providing the necessary cycle flow.

Due to the ultra UV absorbent design and glass vacuum tubing, the ambient external temperature has little if any impact on the temperature of the gas. The only natural element driving this positive process is the free energy provided by the sun's rays.

The system is also fitted with the innovative Solar Bypass Valve. This allows the gas to bypass the panel in heating mode, when the sun is non-existent. i.e. night-time and heavy raincloud.